Bummer! Well, you would know, and that’s why I asked, but this is disappointing for sure.

...I did wonder what would be the mitigating factor, so looked up a few things... (what can I say, I can’t help it.

)

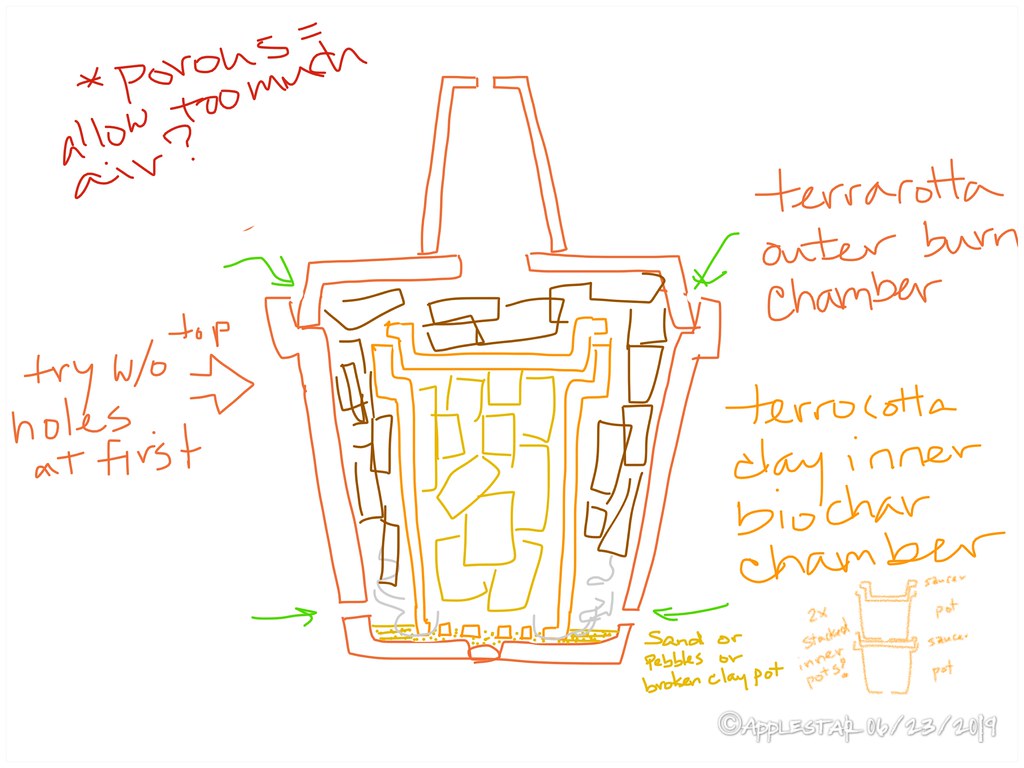

...I think my original thinking (that was probably mistaken) was that terra-cotta pots are “equivalent to clay bisqueware”, and therefore would be able to handle high temperature firing, much higher than what will be needed for wood charcoal. While the references listed below might indicate a small chance that one or more of the pots may be able to survive the ordeal, there are factors that I believe are likely to present and/or reveal defects:

- terra-cotta pots are generally made of impure non-uniform clay mixture rather than the high quality bisqueware that will undergo second high temperature firing after glaze is applied

- these are all used and will have absorbed different levels of moisture and organic matter “contaminants” that will affect their behavior under heat stress

- my mishmash collection of clay pots and saucers will Be from different sources/production processes so their behavior under fire will not be the same, and it’s exactly this kind of non-uniform expansion/contraction properties that can cause cracking and shattering

- the outer large terra-cotta is actually Italian frost resistant type, which means it is somewhat vitreous — I think that’s also why it was holding water. But this type while stronger and weathers better, is more likely to shatter/crack in direct heat....

- assuming everything proceeds as intended, in the above the workshop video (1st one) the presenter said when the flammable gases from inner chamber are pushed out and reaches the outer firing chamber, there will be an explosive burst of temperature surge. That sounds like when the pots would definitely crack, even though they might have been heated slowly and more evenly until then as the temperature in the chambers rise.

Let’s see — here are the references I’m drawing these conclusions from:

Rice University › news › 2012/03/22

Cooking better biochar: Study improves recipe for soil additive - Rice University News & Media

Mar 22, 2012 · For all feedstocks, the researchers found that biochar produced at temperatures above 450 degrees Celsius (842 degrees Fahrenheit) had optimal properties for improving soil drainage and storing carbon.

...

there are 'cones' that melt at different temperatures.

...

How to Find, process, and fire clay without a kiln

https://www.goshen.edu/art/DeptPgs/rework.html

WHY IS CLAY FIRED?

Clay becomes pottery at temperatures at about 1,000 degrees F (the beginning of glowing red heat - about 540 C). Traditionally, tribal earthenware is fired to about 1,400 degrees F (760 C). Heat removes the molecular water in the clay. The heat converts clay molecules to molecules that do not dissolve or slake in water. In modern societies pottery and brick is fired in kilns to temperatures ranging from 1,800 F to 2,400 F. Most of the common clays like clay shown here on the left found in our back yards start to deform and melt if they are fired higher than about 1,900 F. Modern toilets are fired from clay that has fewer contaminants. It is fired to 2,300 to 2,400 F., making it very strong and impervious.

Terra cotta

It is fired at much lower temperatures than stoneware so, not surprisingly, it is not nearly as strong. However fired terra cotta ware has a much better ability to withstand sudden temperature changes without cracking.

—

Debunking the Terracotta Mythos - Eye of the Day Garden Design Center

https://www.eyeofthedaygdc.com/2014/09/ ... ta-mythos/

Low fire clays, having been fired to their maximum temperature (anywhere from 1800-2100°F) remain porous, while high fire clays vitrify when fired to higher temperatures ( 2200-2500° F). Since clays have many “ingredients” that are specific to their particular region, all clays have a different temperature range, but all can be classified as either low fire or high fire clay. Terracotta is technically a red earthenware, a low fire clay containing between 5 and 10% iron.

[...]

It is best to speak of terracotta regionally, for example Mexican terracotta is essentially the same as Italian, but fired at a lower temperature. Another mistake about terracotta is that it is weak. In many places in the world it is hard to find even enough fuel to bring the fire up to the maturation temperature of the clay. If the temperature that matures (hardens, strengthens) the red clay is 1980°F, but the fire only reaches 1800°F, what happens? You have immature, under-baked pottery that is susceptible to cracking and doesn’t last very long.

—

Can You Oven Cook With Pottery?

https://oureverydaylife.com/can-oven-co ... 42986.html

While pottery may seem fragile -- and it does break on impact -- clay vessels are hardened at high temperatures in a kiln. Clay cookware isn’t damaged by indirect oven heat, but direct heat from a stove top or open flame can cause it to shatter.

—

Clay Pot Cooking, Stoneware, China, Earthenware, flameware.

https://www.claycoyote.com/clay-pot-coo ... g-in-clay/

EARTHENWARE

Lower fired clays (1800 to 2000 degF) are considered earthenware. They may be glazed or unglazed (think Romertopf) and some of them, with care, can even take direct heat. Because of the lower firing temperature, earthenware is typically still porous but crystalline silica is not formed. It is somewhat fragile because of the lack of vitrification of the clay body.

—

What Is 'Bisque' in Pottery Terms

https://www.thesprucecrafts.com/bisque-2745994

* Bisque refers to ware that has been fired once and has no chemically bonded water left in the clay. Bisque is a true ceramic material, although the clay body has not yet reached maturity. This stage is also sometimes called biscuit or bisc.

* Bisqueware is the term for pots that have been bisqued—fired for the first time. The pots may also be called biscuit ware.

* To bisque is to fire the clay for the first time.

* Bisque fire is the first firing and is usually only to between cones 08 and 06—1720 and 1835 degrees F or 945 and 1005 degrees C.